Your cart is currently empty!

Practical Maintenance Guide for A4 Paper Cutting and Packing Machines

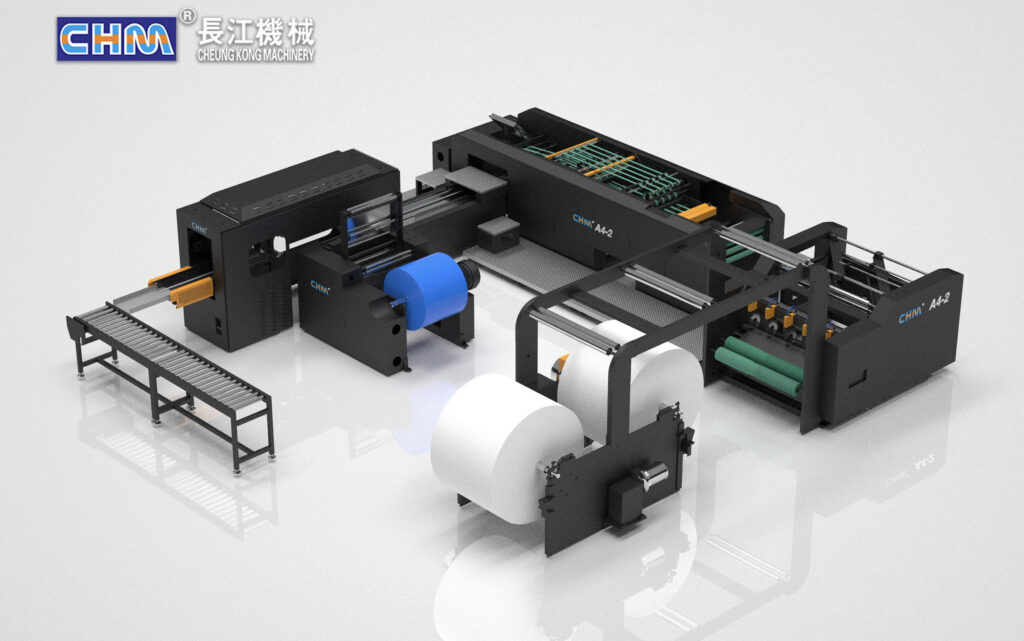

Your machine is the heartbeat of your industrial operations, and like any vital organ, it requires regular care and attention to function optimally. This practical maintenance guide aims to provide you with the steps and insights to keep your machine (model CHMA4-4(5-roll)) running smoothly and efficiently.

Daily Checklist: Quick Wins for Reliable Performance

- Grease Nipples: Ensure all grease nipples are lubricated weekly to prevent wear and tear on bearings.

- Conveyor Belts: Check for slippage or misalignment and adjust accordingly to maintain accurate cutting.

- Cleanliness: Keep the machine clean and free of debris to prevent dust and dirt from affecting performance.

Monthly Inspection: Preventative Measures for Longevity

- Hydraulic Oil Tank: Check the oil level and condition monthly. Replace or top up if necessary.

- Cutting Head: Inspect the cutting head for wear and damage. Replace blades or parts as needed.

- Fans and Filters: Clean the fans and filters to maintain optimal cooling and airflow.

Biannual or Annual Service: Deep Dive for Revitalization

- Internal Inspection: Perform a thorough inspection of the machine’s internals, checking for wear, corrosion, or damage.

- Calibration: Adjust and calibrate the machine’s precision to ensure accurate cutting and performance.

- Dynamic Testing: Test the machine’s dynamic performance to identify any potential issues or areas for improvement.

Tips and Tricks from the Field

- Regular Training: Ensure operators are trained on proper usage and maintenance procedures.

- Preventative Spares: Keep a small stock of spare parts like blades and bearings for quick replacements.

- Maintenance Logs: Maintain a detailed maintenance log to track maintenance activities and identify trends.

Your Input Is Valued

Your experience and insights are invaluable. Share your maintenance tips, challenges, and solutions in the comments below. Your feedback will help us refine this guide and provide even more practical advice.

Remember, a well-maintained machine is a powerful asset that can significantly contribute to your operational efficiency and profitability. Take the time to care for your machine, and it will reward you with reliable and consistent performance.